Wheels

How could wooden wheels support 7+ tons (14,000 lbs) of iron ballast? Simon must have loaded and unloaded the ballast with his sub in the water and that seemed to be a lot of work! But the only way around it is to use a beefy undercarriage, and the first thing that came to mind was while I was driving down the Oklahoma Highway looking for ideas. Stopping along the way, I was looking at the junk piles every farmer and rancher keep and realized the best way might be to use an old tractor chassis for the drive and steering section. Put a chain dive to the drive shaft where the engine would normally be. Just and idea.

Types of link drives

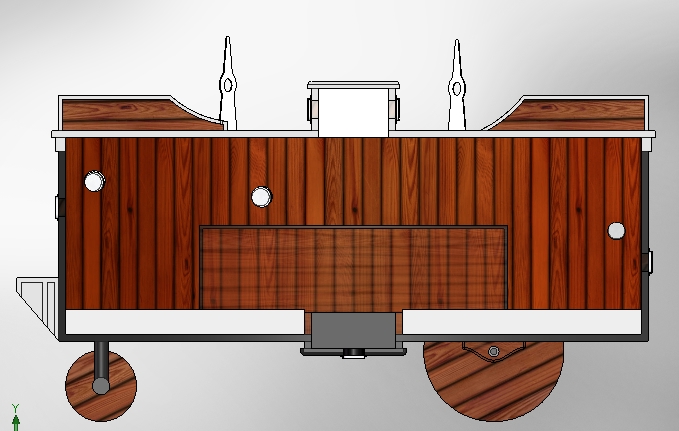

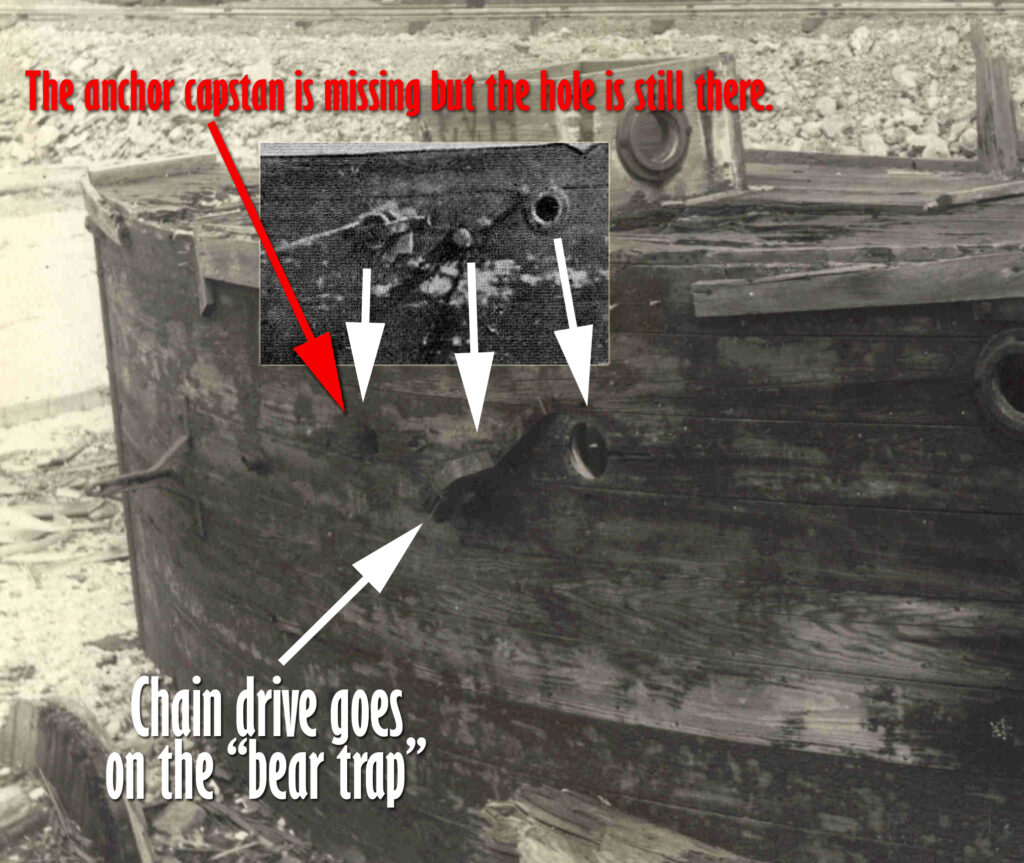

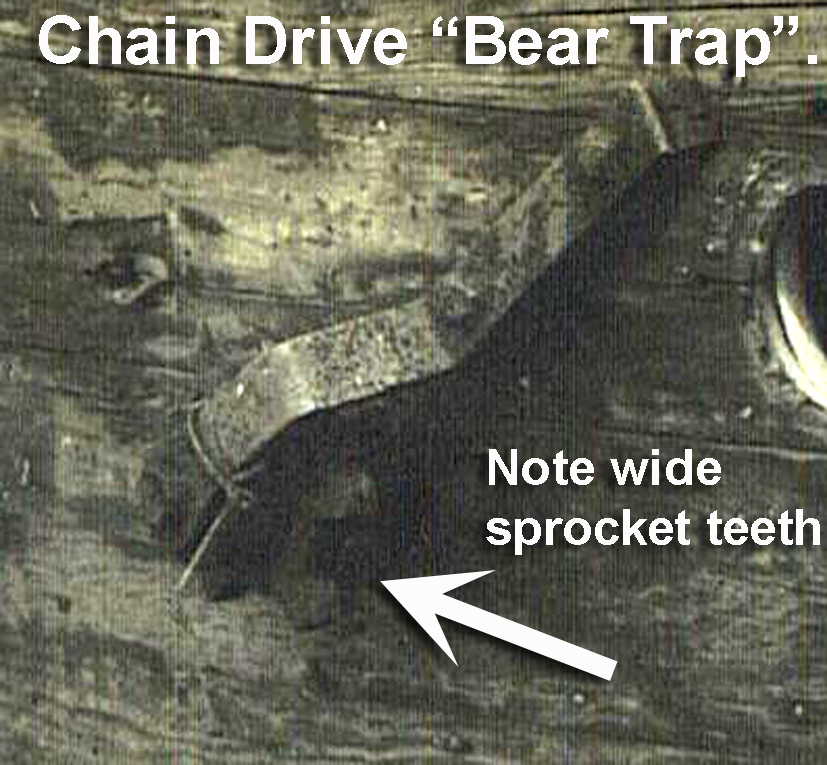

Looking at the exterior view, it appears that the drive wheel sprocket was about 5 times the size of the top one – that should give a pretty good ratio.

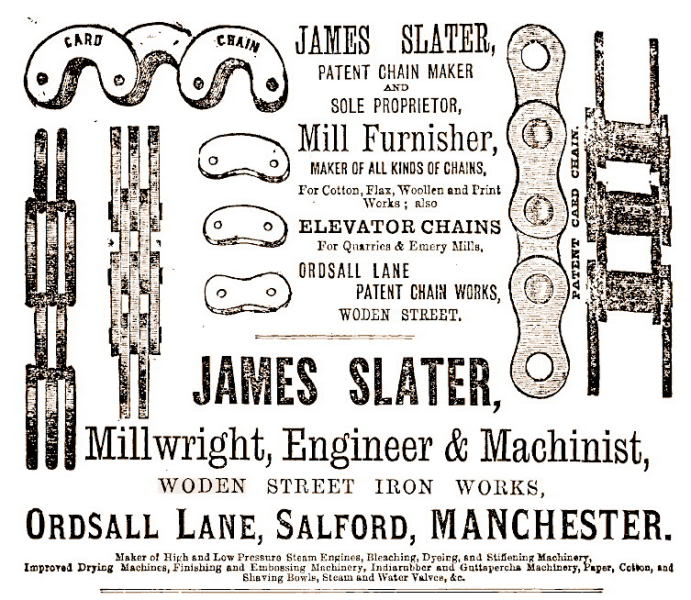

Ladder chain and sprockets manufactured today and in 1893 by Hale Brothers Company.

For the Argonaut Jr. model at the Royal Navy Submarine Museum in Gosport, England, the builders chose cogs that would dive standard chain.

We were not really not sure what kind of chain Simon used to drive the wheel. Common link chain would have been easy to get but it would be prone to slipping off and Simon mentions the chain slipping off the drive wheel on one occasion.

Tim Smalley enlarged the photo and altered the contrast. The result clearly shows sprocket teeth, meaning that Simon did indeed use a sprocket type chain. Most likely a ladder chain which was commonly used on farm implements and industrial machinery. Ladder chain is still manufactured today by the Hale Brothers Company which started business in 1893 only 320 miles Atlantic Highlands where Simon built the Argonaut Jr.

Choices, choices…

Simon might have chosen roller chain which is commonly used on bicycles. It was not new, Leonardo da Vinci drew sketches of it and James Slater patented it in 1864 and it was already in use on bicycles in 1894. The Argonaut Jr. 2010 ultimately used a #50 roller chain which is 5/8″ pitch and 1/2″ wide. It has a working load over 1000 pounds, it is good about not slipping off, and it’s commonly available. We cut the sprockets for it from steel plate using a plasma CNC table. The pattern for the sprockets can be calculate dand drawn in CAD using the information found on this web site: www.gizmology.net/sprockets.htm Or better yet we found a free program that does all of the work for us. See Jason’s Sprocketeer 2 program.

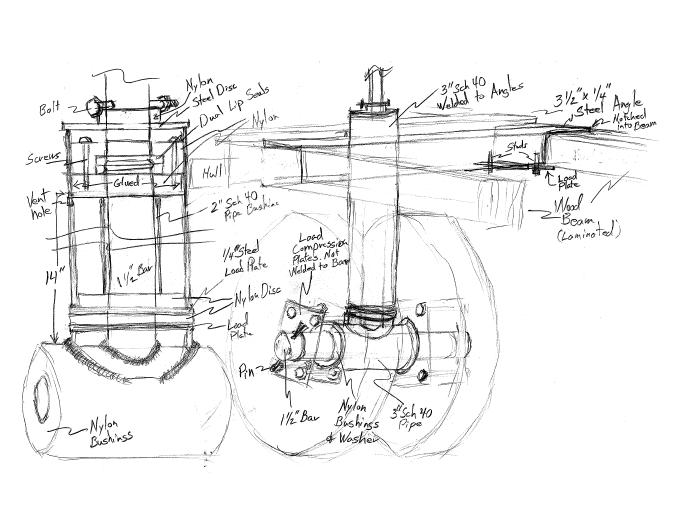

UHMW polyethylene is inside the mounting blocks around the steel axle so that the axle can turn easily. The wheels mount onto pipes that slip over and are then bolted to the axle. This allows for each wheel to be removed separately if needed for repairs.

We cut a #50 chain sprocket with 120 teeth that was connected to a 10 tooth sprocket on the hand crank giving us a 1 to 12 drive ratio.

The large wheels have a height, or diameter of 39.25 inches, so the circumference or distance around the wheel is Pi or 3.15 x 39.25, which is 123.64 inches or 10.3 feet. Twelve 12 turns on the hand crank inside the submarine will move the sub over 10 feet.

So, What’s the hitch?

Is that a hitch for towing?

Simon tested Argonaut Jr. in the Shrewsbury River and then demonstrated it some 2 to 3 miles away in Sandy Hook Bay on the north side of Atlantic Highlands, NJ. While it is possible he towed the Argonaut Jr. to the demonstration site behind a boat, it is also possible that he towed it to the site behind a horse. The Argonaut Jr. did have wheels, but try to explain the purpose of the hitch like structure near the small wheels.

We did get some good information of the Yahoo CarriageDriver forum. The hitch might have been a simple tow point but it was not a suitable hitch for horses. It would have required two horses to pull the 2000 pound Argonaut Jr. and without a proper hitch tongue and brakes, even a few miles would have been a difficult. More likely Simon and Bart towed, rowed or paddled the Argonaut Jr. the 3 to 4 miles from the test site in the Shrewsbury River to the demonstration site in Sandy Hook Bay.

And the small wheel?

There was only one chain to the larger wheels on Argonaut Jr., and with both of the larger wheels turning together the small wheels would have to provided steering both on the bottom and as a rudder when on the surface. When not on the bottom they would also provide a rudder for Argonaut Jr. A short arm, or tiller will go on top of the vertical staff inside the submarine.

UHMW or Ultra High Molecular Weight polyethylene is much like the better know nylon. It makes a great bearing for axels where ball bearings would need to be kept dry and lubricated. If you need a bit of this for a project, then look at the cutting board in your kitchen it is likely made from UHMW. Simon likely used oak or other hard wood around the axel and tiller shaft, but he would have liked UHMW.

O-ring seals are installed inside the pipe to prevent leaks. Simon would have likely used cotton packed tightly around the shaft in what is called a “stuffing box”, but “stuffing boxes tend to leak, so we’ll use o-rings.

Building the wheels

Once the wheels were initially glued together, they were flipped over so the bottom side could be coated with epoxy and the center steel hubs glued into place.

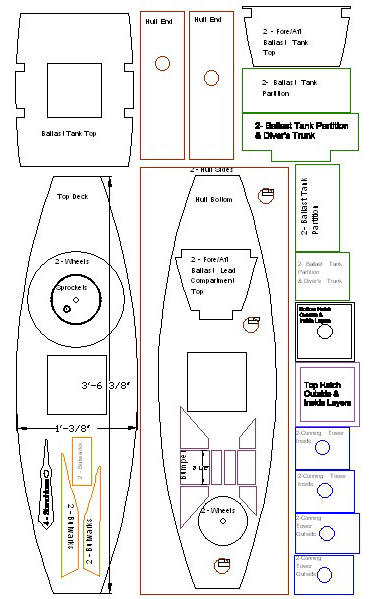

The wheels for our Argonaut Jr. were built from three layers of 2 x 8 lumber. The hub has four bolts that compressed the center of the lumber together but no other mechanical fasteners were used. The wheels on the original Argonaut Jr. were likely 2 layers of 2 x 6 lumber, but in 1842, 2 x 6 lumber was really 2 inches thick by 6 inches wide. Today’s 2 x 6 lumber actually measures 1 1/2 inches by 5 1/2 inches.

So, Simon’s wheels were likely 4 inches wide, while ours will be 4 1/2 inches wide. Simon would have also used nails or bolts to hold the layers together, and we chose to use nothing but epoxy. The epoxy is not only a strong glue but it also seals the wood from the water, helping it to remain stronger.

We planed the edges of the wheels and coated them with epoxy. The axel mounting blocks were built from laminated 2 x 8’s and pieces of UHMD plastic that lined the inside and acted as a bearing block that allowed the axle to turn.

Once the bottom deck was ready with the drop weight system installed, we glued and bolted the axel to the bottom frame beams then we flipped it back upright and installed the wheels after covering them with truck tire tread picked up from C & C Tire in Tulsa.

Resources

http://www.harderwoods.com/pipetemplate.php Pipe Joint Template

http://www.engineeringtoolbox.com/ansi-steel-pipes-d_305.html ANSI Sch40 Steel Pipe Sizes

http://www.engineeringtoolbox.com/ansi-steel-pipes-d_306.html ANSI Sch80 Steel Pipe Sizes